- +86-130-1868-1456

- jdpack_sales01@china-jingduan.cn

In today’s global logistics and manufacturing environment, pallets remain the backbone of cargo handling. From e-commerce warehouses and food processing plants to chemical factories and building material distribution centers, palletized cargo is everywhere. However, securing pallets efficiently, safely, and consistently is still a challenge for many companies.

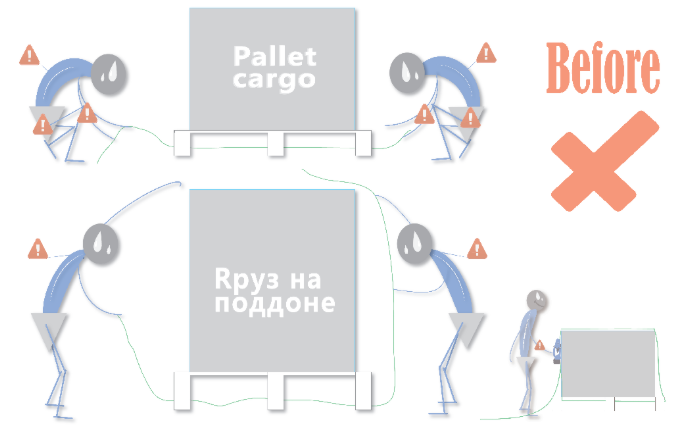

For decades, manual pallet strapping has been considered a “low-cost” solution. In reality, it is one of the most underestimated sources of inefficiency, injuries, and hidden operational costs. Repetitive bending, squatting, lifting heavy strapping tools, and walking around pallets hundreds of times per shift take a serious toll on workers’ health and productivity.

This is exactly where ergonomic pallet strapping machines come into play.

The JD-008 (JD-009) Ergonomic Pallet Strapping Machine represents a new generation of pallet strapping solutions—combining ergonomic design, high efficiency, touch-screen control, and patent-safe innovation into one elegant system.

Many managers once asked:

“Is pallet strapping really worth automation?”

The answer becomes clear when you look at daily operations.

A typical scenario:

60 pallets per day

4 straps per pallet

That means an operator may need to:

Bend down hundreds of times

Thread straps under pallets manually

Lift straps from the ground repeatedly

Carry a heavy battery strapping tool all day

Often require two operators for tall or heavy loads

Over time, this results in:

Back and knee injuries

Wrist and shoulder strain

Fatigue and low morale

Increased sick leave and staff turnover

Manual strapping is not only slow—it is physically unsustainable.

The JD-008 ergonomic pallet strapping machine was developed around a simple yet powerful idea:

One person. One side. Zero bending.

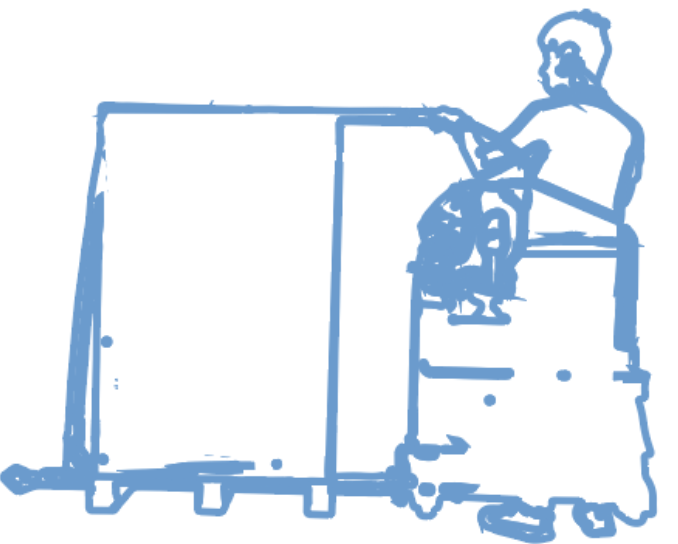

Thanks to its unique working principle and optimized structure, JD-008 allows operators to complete pallet strapping without bending down, without crawling under pallets, and without carrying heavy tools.

Just roll the machine to the pallet, operate the joystick, and the system takes care of the rest.

Move JD-008 in front of the pallet

Set parameters on the touch screen

Push the joystick forward

The ChainLance system automatically feeds the strap through the pallet opening, around the load, and back to the operator

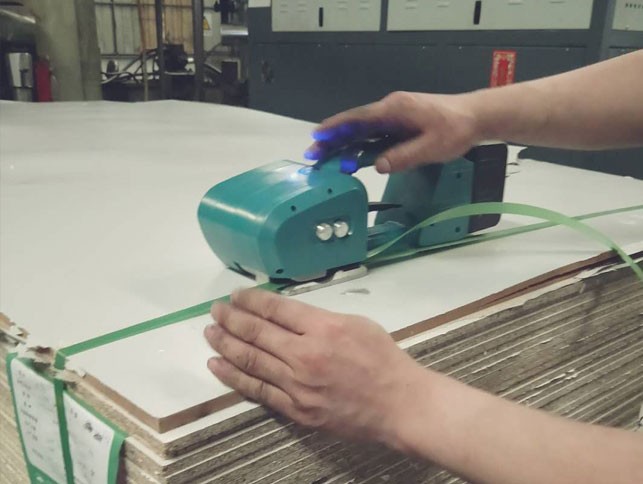

Strap is tensioned and sealed using a compatible battery strapping tool

All key movements are done at standing height, eliminating harmful postures.

Frequent bending and squatting

Manual threading under pallets

Heavy tool handling

Inconsistent tension

Difficult for tall pallets (2.5 m+)

Often requires multiple workers

0 bending down

0 manual threading under pallets

0 lifting straps from the floor

0 carrying heavy tools

One operator from one side

Easily secures pallets up to 2.6–2.8 meters high

The difference is not incremental—it is transformational.

Automatically threads the strap through the pallet without manual bending or crawling.

Simple parameter setting improves accuracy, repeatability, and ease of use.

Ensures strong thrust, stable feeding, and reliable performance under heavy loads.

Supports:

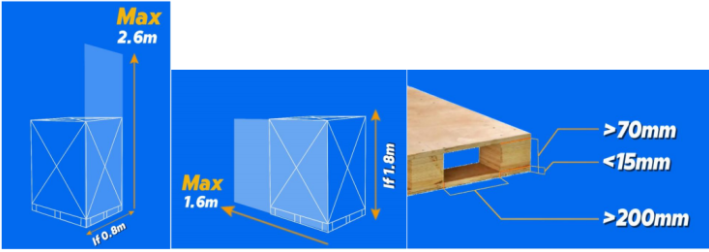

Strap width: 12–16 mm (19 mm optional)

Strap thickness: 0.6–1.3 mm

Handles pallet loads up to 2.6–2.8 m height, ideal for:

Building materials

Chemical drums

Industrial goods

33V lithium battery

400–600 strapping cycles per charge

Fast charging (~3.5 hours)

Fully mobile, no fixed installation

Flexible connection structure allows matching with different battery strapping tools.

One of JD-008’s most important strengths lies beyond hardware.

Its unique working principle and structural layout are independently developed, allowing the system to:

Avoid foreign patent conflicts

Provide worry-free solutions for distributors

Reduce legal and commercial risks in international markets

For partners and distributors, this is not just a machine—it is long-term security.

From a commercial perspective, JD-008 delivers value on multiple levels:

Higher throughput with fewer workers

Reduced injury risks and compensation costs

Shorter training time

Lower long-term operating costs

Easier market entry thanks to patent safety

Its compatibility with different sealing heads and strapping materials further reduces customer switching costs, making it highly attractive for distributors building local markets.

JD-008 is designed with sustainability in mind:

Energy-efficient motors

Optimized electronic control system

Extended battery lifespan

Support for recyclable PET and PP straps

Durable structure for long service life

At the same time, it significantly improves working conditions—demonstrating genuine care for people, not just productivity.

One of the most elegant ways to secure pallet cargo today is to work with the JD-008 Pallet Strapping Machine / System.

It transforms pallet strapping from a physically demanding task into a safe, efficient, and sustainable operation, helping companies move faster while protecting their most valuable asset—their people.

Welcome all global distributors join us to win mutual benefit

Successful Case Analysis of Guangdong Shaoguan Perforated Brick Packaging

Application case for packing LED product with JD-008 Pallet strapping machine

Successful application of fine-end brick manual packaging scheme in Guangxi Rotary Kiln Brick Factory