- +86-130-1868-1456

- jdpack_sales01@china-jingduan.cn

Why a Battery Strapping Tool Can Significantly Reduce Your Cargo Securing Cost?

In today’s logistics and manufacturing environment, end-of-line packaging efficiency directly affects operating costs, labor health, and shipment safety.

However, many factories and warehouses are still using manual strapping tools with metal buckles—a method that is not only inefficient, but also costly in the long run.

In this article, we explain how a battery strapping tool helps you save money when securing cargo, using real consumption calculations and practical comparisons.

Manual strapping tools usually rely on:

Steel or metal buckles

Manual tensioning and sealing

High labor intensity and time consumption

Although the initial investment looks low, the hidden costs add up quickly:

Continuous purchase of metal buckles

Slower packing speed

Higher labor fatigue and injury risk

Inconsistent strap tension, affecting cargo safety

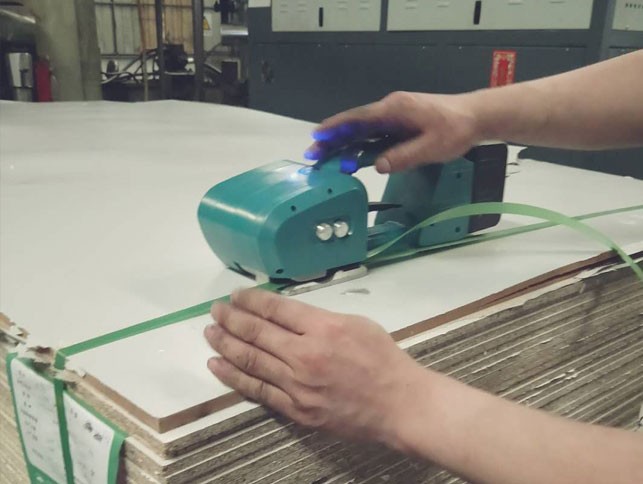

A battery-powered strapping tool uses friction weld sealing, eliminating the need for metal buckles completely. This single change already brings a clear cost advantage.

PET strap width: 16 mm

PET strap thickness: 0.8 mm

Strap weight: 1 ton

Pallet size: 1.2 m × 1.2 m

Straps per pallet: 4 straps

1 roll = 1,250 meters

1 ton = 50 rolls

Total strap length:

50 × 1,250 m = 62,500 meters

Metal buckle unit price: ¥0.1 per piece

Each strapping point requires 1 buckle

When consuming 1 ton of PET strap, the cost of metal buckles alone reaches:

Welcome all global distributors join us to win mutual benefit

Successful Case Analysis of Guangdong Shaoguan Perforated Brick Packaging

Application case for packing LED product with JD-008 Pallet strapping machine

Successful application of fine-end brick manual packaging scheme in Guangxi Rotary Kiln Brick Factory